Antenna Construction Details

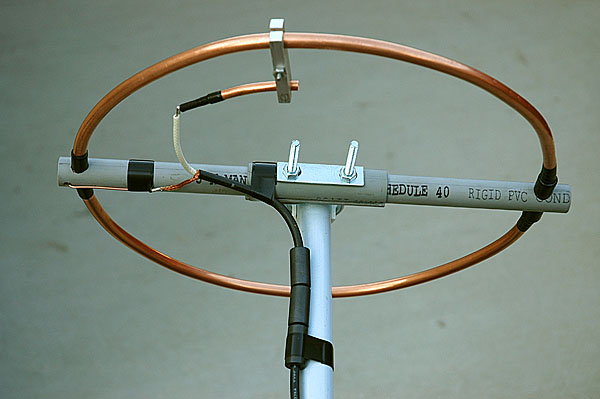

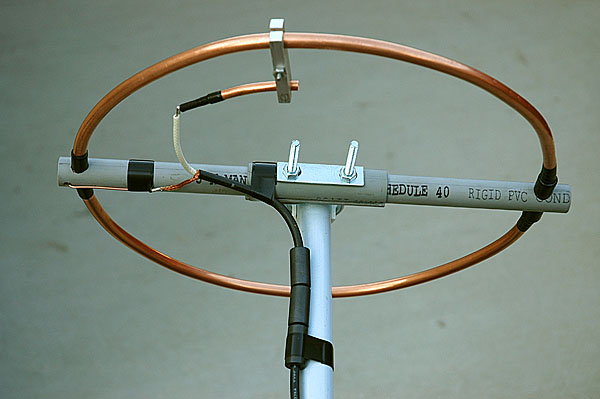

The first item that I will describe is the boom. This is used to secure the antenna to the

mast. It also holds the two ends of the antenna loop apart. The boom is made out of schedule

40 PVC electrical conduit. This material is good because it is an insulator and is also

made to be UV light resistant. It is also easy to work with. I used 1/2" conduit for the

boom and 3/4" to beef up the center section of the boom where it will be bolted to the

mast. 1/2" conduit will not normally fit into 3/4" conduit so I split the 3/4" conduit down one

side by cutting it with a hack saw. This allowed me to force the 1/2" conduit into the split

3/4" conduit. You can see the widened split in the 3/4" section in the enlarged picture. The

boom is 14-1/2" long and the center 3/4" section is 4" long. To install the split 3/4" conduit

over the 1/2" conduit I drove the 1/2" boom into the 3/4" section with a rubber mallet until

the 3/4" section was on the 1/2" section. Then I used a deep socket wrench socket that was

lager enough to fit over the 1/2" section but not large enough to fit over the 3/4" section

to further drive the 3/4" section toward the center of the boom. I finished driving the 3/4"

section to the center of the boom by placing the 1/2" section in a vice that was not

tightened down on 1/2" section but was closed enough so that it would not allow the 3/4"

section to pass by the vice jaws. That way I was able to complete driving the 3/4" section to

the middle of the boom by tapping on the end of the 1/2" boom with the rubber mallet. Once

that was done I drilled the necessary holes. Two in the center for the U-bolt to go through

and one at each end of the boom that are larger. One hole for the radiating element and one

slightly larger hole on the other end for the spreader. The spreader is a piece of PVC that I

happened to have on hand. It had an inner diameter that was large enough so that the 3/8" copper

radiating element could be inserted into it. The spreader is 2" long and the radiating

element is inserted 1/4" into it so that the two ends of the copper loop are separated by 1-1/2".

The first item that I will describe is the boom. This is used to secure the antenna to the

mast. It also holds the two ends of the antenna loop apart. The boom is made out of schedule

40 PVC electrical conduit. This material is good because it is an insulator and is also

made to be UV light resistant. It is also easy to work with. I used 1/2" conduit for the

boom and 3/4" to beef up the center section of the boom where it will be bolted to the

mast. 1/2" conduit will not normally fit into 3/4" conduit so I split the 3/4" conduit down one

side by cutting it with a hack saw. This allowed me to force the 1/2" conduit into the split

3/4" conduit. You can see the widened split in the 3/4" section in the enlarged picture. The

boom is 14-1/2" long and the center 3/4" section is 4" long. To install the split 3/4" conduit

over the 1/2" conduit I drove the 1/2" boom into the 3/4" section with a rubber mallet until

the 3/4" section was on the 1/2" section. Then I used a deep socket wrench socket that was

lager enough to fit over the 1/2" section but not large enough to fit over the 3/4" section

to further drive the 3/4" section toward the center of the boom. I finished driving the 3/4"

section to the center of the boom by placing the 1/2" section in a vice that was not

tightened down on 1/2" section but was closed enough so that it would not allow the 3/4"

section to pass by the vice jaws. That way I was able to complete driving the 3/4" section to

the middle of the boom by tapping on the end of the 1/2" boom with the rubber mallet. Once

that was done I drilled the necessary holes. Two in the center for the U-bolt to go through

and one at each end of the boom that are larger. One hole for the radiating element and one

slightly larger hole on the other end for the spreader. The spreader is a piece of PVC that I

happened to have on hand. It had an inner diameter that was large enough so that the 3/8" copper

radiating element could be inserted into it. The spreader is 2" long and the radiating

element is inserted 1/4" into it so that the two ends of the copper loop are separated by 1-1/2".

The next item is the gamma clamp which is also shown in the picture. This is used to

clamp the gamma tube to the radiating element as well as have the ability to be moved. The

ability to move the clamp allows you to to move the feed point on the radiating element

as well as vary the capacitance of the gamma tube. The clamp was made out of 5/16" aluminum

square stock that I just happened to already have. A hole is drilled through the center of

each piece to allow a screw to be used to clamp the two bars together. I also drilled two

different diameter arcs near the end of each section. I used two different drill sizes to

match the radius of the two different copper tube diameters. The arcs are not complete

semi-circles because I wanted the two bars to be able to clamp to the copper tubes without

touching each other. That way I could ensure a tight fit once the clamp is tightened down.

The way I accomplished this was to put a spacer between the two bars of metal and clamp

them together prior to drilling. I then drilled a hole in the center of the spacer which

left an arc cut into each metal clamp bar.

The picture on the left shows the copper tube for the radiating element being measured

in preparation for cutting. The radiating element is a single piece of copper tube.

I calculated the length of the element by calculating what the length should be

at 1/2 wave length at 144.250MHz. I don't use the formulas normally found in books because

I tend to forget the exact number used. I just calculate it using the speed of light as

a starting point. The speed of light is approximately 186000 miles per second in free space.

Yes I know that 186000 miles per second is not exact but it is close enough for our

purposes. I want to convert 186000 miles to a number that will mean something to me. So I

converted the distance to feet. There are 5280 feet per mile so (186000 miles X 5280 feet

= 982080000 feet). We now need to divide the number of feet traveled in one second by the

target frequency (982080000/144250000 = 6.8 feet). Then to convert 6.8 feet to inches

(6.8 feet X 12 inches - 81.6 inches). 81.6 inches is how long one wave length is at 144.250MHz.

Since the propagation velocity of the signal traveling through the copper element is somewhat

less than the speed of light through free space I used 98% as a multiplying factor. So

(81.6" X .98 = 79.97"). I just rounded 79.97" off to 80". The loop is 1/2 wave length so I

divided 80"/ 2 to arrive at 40" for the final length of the copper radiating element. I

measured the tube buy first carefully straightening out the tube then measuring 40" as shown

in the picture. Please note that you should mark the center point for the ground connection

point at this step of the process. That is what is shown in the second picture on the right.

The picture on the left shows the copper tube for the radiating element being measured

in preparation for cutting. The radiating element is a single piece of copper tube.

I calculated the length of the element by calculating what the length should be

at 1/2 wave length at 144.250MHz. I don't use the formulas normally found in books because

I tend to forget the exact number used. I just calculate it using the speed of light as

a starting point. The speed of light is approximately 186000 miles per second in free space.

Yes I know that 186000 miles per second is not exact but it is close enough for our

purposes. I want to convert 186000 miles to a number that will mean something to me. So I

converted the distance to feet. There are 5280 feet per mile so (186000 miles X 5280 feet

= 982080000 feet). We now need to divide the number of feet traveled in one second by the

target frequency (982080000/144250000 = 6.8 feet). Then to convert 6.8 feet to inches

(6.8 feet X 12 inches - 81.6 inches). 81.6 inches is how long one wave length is at 144.250MHz.

Since the propagation velocity of the signal traveling through the copper element is somewhat

less than the speed of light through free space I used 98% as a multiplying factor. So

(81.6" X .98 = 79.97"). I just rounded 79.97" off to 80". The loop is 1/2 wave length so I

divided 80"/ 2 to arrive at 40" for the final length of the copper radiating element. I

measured the tube buy first carefully straightening out the tube then measuring 40" as shown

in the picture. Please note that you should mark the center point for the ground connection

point at this step of the process. That is what is shown in the second picture on the right.

After measuring the center point and marking it, I cut the copper to size. You will notice

that the copper is being held in a vice, but please note that this has to be done carefully!

The vise shown in the picture has rubber covers over the metal vise jaws to help protect

the surface of the soft copper. Also the vise is clamped on to the copper very lightly, just

enough to hold the copper in place while the cut is being made with the hack saw. If you

clamp down too tightly the copper tube will be crushed. The second picture shows the end of

the copper tube after it was cut. Notice how rough the end of the tube looks. Before

proceeding I smoothed off the ends of the tube with a file. I also used a knife to take the

burred edges off the inside edge of the tube.

After measuring the center point and marking it, I cut the copper to size. You will notice

that the copper is being held in a vice, but please note that this has to be done carefully!

The vise shown in the picture has rubber covers over the metal vise jaws to help protect

the surface of the soft copper. Also the vise is clamped on to the copper very lightly, just

enough to hold the copper in place while the cut is being made with the hack saw. If you

clamp down too tightly the copper tube will be crushed. The second picture shows the end of

the copper tube after it was cut. Notice how rough the end of the tube looks. Before

proceeding I smoothed off the ends of the tube with a file. I also used a knife to take the

burred edges off the inside edge of the tube.

The next step is to carefully bend the tube back into a circular shape as seen in the left

picture. It is easier to measure the tube when it is straight. If you try to measure it while

it is still in a circular shape right from the roll it will be very difficult to measure

because the inner and outer diameter will measure two different values. I found it was

more reliable to straighten out the tube, make the measurement, cut it and then bend it

back into a circle. Please note that you need to be careful while bending the tube because

you could put a kink in it very easily. When bending the tube, do it in small steps and move

your bend locations along the length. To get it close to the right shape and size use something

that is about the right size as a form to bend the tube around. I found a five gallon plastic

bucket worked pretty well as a guide. The picture on the right shows the boom being installed

on the radiating element. Also note that I have slipped two pieces of plastic yellow shrink

tube on each end of the copper tube. This is a refinement of my assembly process. The shrink

tube will be installed in one of the next steps.

The next step is to carefully bend the tube back into a circular shape as seen in the left

picture. It is easier to measure the tube when it is straight. If you try to measure it while

it is still in a circular shape right from the roll it will be very difficult to measure

because the inner and outer diameter will measure two different values. I found it was

more reliable to straighten out the tube, make the measurement, cut it and then bend it

back into a circle. Please note that you need to be careful while bending the tube because

you could put a kink in it very easily. When bending the tube, do it in small steps and move

your bend locations along the length. To get it close to the right shape and size use something

that is about the right size as a form to bend the tube around. I found a five gallon plastic

bucket worked pretty well as a guide. The picture on the right shows the boom being installed

on the radiating element. Also note that I have slipped two pieces of plastic yellow shrink

tube on each end of the copper tube. This is a refinement of my assembly process. The shrink

tube will be installed in one of the next steps.

The next step is to attach the split end of the copper radiating loop to the spreader tube.

Before doing this I measured about 1/4" in on each end of the radiating loop and marked that

location. That way I would know where to position the copper element relative to the spreader

tube. What you can't see in this first picture is the yellow heat shrink tube that has been

slid around to the far side of the loop, just beyond view. After both sides of the loop were

attached using electrical tape the heat shrink tube was slide back around and over the spreader

tube. This is shown in the center picture. I used 1/2" heat shrink tube that was cut to 1-1/2"

long. Once the heat shrink was positioned correctly I heated it up with a heat gun to shrink

it into place. This process is shown in the third picture. The heat shrink will now cover

the tape joint which should keep out any moisture when it rains. The heat shrink should also

protect the tape from coming off due to exposure to the weather.

The next step is to attach the split end of the copper radiating loop to the spreader tube.

Before doing this I measured about 1/4" in on each end of the radiating loop and marked that

location. That way I would know where to position the copper element relative to the spreader

tube. What you can't see in this first picture is the yellow heat shrink tube that has been

slid around to the far side of the loop, just beyond view. After both sides of the loop were

attached using electrical tape the heat shrink tube was slide back around and over the spreader

tube. This is shown in the center picture. I used 1/2" heat shrink tube that was cut to 1-1/2"

long. Once the heat shrink was positioned correctly I heated it up with a heat gun to shrink

it into place. This process is shown in the third picture. The heat shrink will now cover

the tape joint which should keep out any moisture when it rains. The heat shrink should also

protect the tape from coming off due to exposure to the weather.

Now you can see the antenna loop after the spreader assembly has been completed. Also shown in

this picture are the gamma tube clamp and the shim that will be used between the U-bolt and

the mast. Notice how the heat shrink tube is now formed over the spreader and conforms to the

smaller diameter of the copper tube as well. The second picture shows the loop after the gamma

clamp and tube have been attached. Also the U-bolt was reversed to match the other loop that

will eventually become part of the stacked array.

Now you can see the antenna loop after the spreader assembly has been completed. Also shown in

this picture are the gamma tube clamp and the shim that will be used between the U-bolt and

the mast. Notice how the heat shrink tube is now formed over the spreader and conforms to the

smaller diameter of the copper tube as well. The second picture shows the loop after the gamma

clamp and tube have been attached. Also the U-bolt was reversed to match the other loop that

will eventually become part of the stacked array.

The next step is to prepare the ground connection point. In the first picture you can see

the tip of my Weller soldering gun positioned through the end of the boom. In this step I heat

up the ground point of the loop and deposit some solder on the copper tube at that point. In

order for the solder to attach to the copper the soldering point must be hot enough for the

solder to flow on to the copper. Again, this point is at the exact center of the loop, opposite

of the split end. The second step to this process is to solder the ground wire to the loop. I

also prepare the wire by first tinning it with a little solder so that all I would have to do is

to heat up the connection to reflow the solder. This process can be seen in the second picture.

You will notice that I am holding the copper wire with a pair of pliers since the wire will

become too hot to hold.

The next step is to prepare the ground connection point. In the first picture you can see

the tip of my Weller soldering gun positioned through the end of the boom. In this step I heat

up the ground point of the loop and deposit some solder on the copper tube at that point. In

order for the solder to attach to the copper the soldering point must be hot enough for the

solder to flow on to the copper. Again, this point is at the exact center of the loop, opposite

of the split end. The second step to this process is to solder the ground wire to the loop. I

also prepare the wire by first tinning it with a little solder so that all I would have to do is

to heat up the connection to reflow the solder. This process can be seen in the second picture.

You will notice that I am holding the copper wire with a pair of pliers since the wire will

become too hot to hold.

This picture shows the completed antenna from the top. The main reason to show you this is so

that you can view the entire radiating element. This picture was taken before I refined the

assembly process by adding the heat shrink tube over the electrical tape. In the final version

I have also removed the tape on either side of the ground point on the copper loop. You can

see the tape in the picture on the left side of the loop.

This picture shows the completed antenna from the top. The main reason to show you this is so

that you can view the entire radiating element. This picture was taken before I refined the

assembly process by adding the heat shrink tube over the electrical tape. In the final version

I have also removed the tape on either side of the ground point on the copper loop. You can

see the tape in the picture on the left side of the loop.

This picture shows the gamma tube attached to the radiating element through the clamping bars.

The gamma tube is nothing more than a capacitor formed from a piece of 1/4" copper tube and

an insulated wire. The capacitor is made in such a way that you can clamp on to one plate of

the capacitor (which is the copper tube) and attach it to radiating element of the antenna.

The length of the gamma tube for my construction method is 2-1/2" long. The wire going into

the tube is a piece of coax from a car radio antenna. The only reason I chose this type of

wire is that it was the right diameter to fit in the gamma tube and I happened to have a piece

laying around my shop. The shield in the antenna wire acts as one plate of the capacitor while

the copper gamma tube acts as the other plate. The plastic jacket on the coax acts as the

capacitor dielectric. The fit of the coax cable that I chose was fairly tight in the gamma

tube. Just to make sure that the wire didn't move I put a couple of wraps of electrical tape

at the end of the tube to hold the wire in place. The final version will have a piece of heat

shrink tube over the intersection of the copper tube and wire. The length of your gamma tube

will vary depending on how it is constructed. I have read that the average capacitance for

gamma match is about 7pf or less per meter of wave length. In the case of two meters that

would mean that the capacitance should be about 14pf or less. Mine turned out to be a little

over 11pf when adjusted to resonance.

This picture shows the gamma tube attached to the radiating element through the clamping bars.

The gamma tube is nothing more than a capacitor formed from a piece of 1/4" copper tube and

an insulated wire. The capacitor is made in such a way that you can clamp on to one plate of

the capacitor (which is the copper tube) and attach it to radiating element of the antenna.

The length of the gamma tube for my construction method is 2-1/2" long. The wire going into

the tube is a piece of coax from a car radio antenna. The only reason I chose this type of

wire is that it was the right diameter to fit in the gamma tube and I happened to have a piece

laying around my shop. The shield in the antenna wire acts as one plate of the capacitor while

the copper gamma tube acts as the other plate. The plastic jacket on the coax acts as the

capacitor dielectric. The fit of the coax cable that I chose was fairly tight in the gamma

tube. Just to make sure that the wire didn't move I put a couple of wraps of electrical tape

at the end of the tube to hold the wire in place. The final version will have a piece of heat

shrink tube over the intersection of the copper tube and wire. The length of your gamma tube

will vary depending on how it is constructed. I have read that the average capacitance for

gamma match is about 7pf or less per meter of wave length. In the case of two meters that

would mean that the capacitance should be about 14pf or less. Mine turned out to be a little

over 11pf when adjusted to resonance.

There are several things you should notice in this next picture. First is the gamma match that

we were just talking about. Notice that the center conductor of the feed line has been

separated from the shield about 2-1/2". This allows the center conductor to reach over and

be soldered to the gamma coax. It also allows the ground shield to be directed toward the

ground connection point wire. At this point there are a couple of things that I found out

through experimentation that you should keep in mind. #1 it is best to keep the distance

that you have to strip back the shield to a minimum in order to maintain the characteristic

impedance of the feed line as close as possible to the actual connection points.

#2 it is best to have the unshielded feed line approach the gamma feed point as close to a

perpendicular to the tangent angle of the radiating element as possible. This keeps

interactions between the unshielded feed line to the radiating element to a minimum. You

will notice that the angle I have used is a compromise between the angle and the minimum

unshielded distance. #3 don't try to avoid separating the center conductor from the shield

by tying the ground wire further back on the feed line shield to allow the shielded feed

line to go all the way to the gamma match coax feed point. If you tie the ground wire to

a point further back on the feed line shield buy striping away the feed line jacket and

soldering the ground wire to the shield, you will end up with a large impedance miss-match

in the feed line at the solder point that will prevent you from ever obtaining a good

SWR match.

There are several things you should notice in this next picture. First is the gamma match that

we were just talking about. Notice that the center conductor of the feed line has been

separated from the shield about 2-1/2". This allows the center conductor to reach over and

be soldered to the gamma coax. It also allows the ground shield to be directed toward the

ground connection point wire. At this point there are a couple of things that I found out

through experimentation that you should keep in mind. #1 it is best to keep the distance

that you have to strip back the shield to a minimum in order to maintain the characteristic

impedance of the feed line as close as possible to the actual connection points.

#2 it is best to have the unshielded feed line approach the gamma feed point as close to a

perpendicular to the tangent angle of the radiating element as possible. This keeps

interactions between the unshielded feed line to the radiating element to a minimum. You

will notice that the angle I have used is a compromise between the angle and the minimum

unshielded distance. #3 don't try to avoid separating the center conductor from the shield

by tying the ground wire further back on the feed line shield to allow the shielded feed

line to go all the way to the gamma match coax feed point. If you tie the ground wire to

a point further back on the feed line shield buy striping away the feed line jacket and

soldering the ground wire to the shield, you will end up with a large impedance miss-match

in the feed line at the solder point that will prevent you from ever obtaining a good

SWR match.

Other things to notice about the feed line. #1 notice that the shield on the feed line is

soldered to a ground wire that connects to the loop. This allows some flexibility provided

by the braided shield so that the gamma coax can be moved in and out of the gamma tube for

adjustment. It also allows for easy rework of the ground connection if needed. The ground

wire only has to be soldered to the loop one time. You can still unsolder the feed line

from the ground wire if needed. Soldering anything to the loop requires a lot of heat,

so if you can minimize the number of times needed to do this you are better off. This

method requires that you only have to solder to the radiating element once. #2 notice that

I used several toroid cores on the feed line. You can see them resting against the mast.

This was done to enhance the operation of the antenna system by preventing the signal

radiating from the antenna from flowing back down the shield of the feed line.

In the picture you can also see the metal plate on the center section of the boom. This metal

plate came with the U-bolt and is there just to enhance the strength of the boom when the

U-bolt is tightened down. There is also a metal plate on the other side of the boom. I had

extra metal plates from the U-bolts used to attach the fiberglass mast to the mast mounting

plate.

This picture shows the ground point on the radiating element. The ground point is at the

exact center of the copper loop. I used a Weller soldering gun to make this solder joint

(shown in a earlier step). You can see that I have wrapped several layers of electrical

tape around the copper on either side of the boom to hold the radiating element in position.

Since I have connected the ground wire to the loop by feeding it through a small hole on

the end of the boom, the tape is no longer needed and can be removed. You also can see

other construction details from a different angle in this picture.

This picture shows the ground point on the radiating element. The ground point is at the

exact center of the copper loop. I used a Weller soldering gun to make this solder joint

(shown in a earlier step). You can see that I have wrapped several layers of electrical

tape around the copper on either side of the boom to hold the radiating element in position.

Since I have connected the ground wire to the loop by feeding it through a small hole on

the end of the boom, the tape is no longer needed and can be removed. You also can see

other construction details from a different angle in this picture.

This picture shows the other side of the antenna. This shows the spreader. Again, this

picture was taken before I refined the assembly process by adding heat shrink tube over

the electrical tape. The copper radiating element only inserts into the spreader by about

1/4" on either side as described earlier. This keeps the two ends of the loop from

touching and also secures the open end of the loop to the boom. The space between the two

ends of the loop are separated by about 1-1/2". Again I have used electrical tape to secure

everything in place. You may want to use another method such as epoxy cement or some other

means. I chose electrical tape covered with heat shrink tube. It is a good idea to seal the

open ends of the loop to keep water out. When it rains water may collect inside the radiating

element and adversely affect the antenna performance.

This picture shows the other side of the antenna. This shows the spreader. Again, this

picture was taken before I refined the assembly process by adding heat shrink tube over

the electrical tape. The copper radiating element only inserts into the spreader by about

1/4" on either side as described earlier. This keeps the two ends of the loop from

touching and also secures the open end of the loop to the boom. The space between the two

ends of the loop are separated by about 1-1/2". Again I have used electrical tape to secure

everything in place. You may want to use another method such as epoxy cement or some other

means. I chose electrical tape covered with heat shrink tube. It is a good idea to seal the

open ends of the loop to keep water out. When it rains water may collect inside the radiating

element and adversely affect the antenna performance.

Here are a couple more views of the antenna before heat shrink tube was added to the

assembly process. The first photo shows the mast clamp from the other side. Again

notice the metal plate removed from one to the U-bolts used to clamp the mast to the

mast plate. The second picture just shows what you have already seen from a different

angle. You may notice that the U-bolt attaching the boom to the mast is rather long. I

may end up cutting off the extra length before final installation if I feel energetic.

Here are a couple more views of the antenna before heat shrink tube was added to the

assembly process. The first photo shows the mast clamp from the other side. Again

notice the metal plate removed from one to the U-bolts used to clamp the mast to the

mast plate. The second picture just shows what you have already seen from a different

angle. You may notice that the U-bolt attaching the boom to the mast is rather long. I

may end up cutting off the extra length before final installation if I feel energetic.

During my experimentation I had a longer gamma tube. Since it was longer I wanted a

second non-conductive clamp to secure it at the opposite end from the clamping bars.

This picture shows the clamp I made from a piece of the 1/2" PVC. I don't know if I

will use this additional clamp or not but I thought I should show it for additional

reference information.

During my experimentation I had a longer gamma tube. Since it was longer I wanted a

second non-conductive clamp to secure it at the opposite end from the clamping bars.

This picture shows the clamp I made from a piece of the 1/2" PVC. I don't know if I

will use this additional clamp or not but I thought I should show it for additional

reference information.